Industrial weighing scales play a pivotal role in diverse sectors, ensuring precise measurement and efficient operations. In today’s rapidly evolving industries, the need for accurate weighing solutions has become paramount. Let’s delve into the significance and applications of industrial weighing scale, exploring their various types and factors influencing performance, installation, calibration, maintenance, and more.

Industrial Weighing Scale Applications

Manufacturing

In manufacturing environments, precision is critical to optimizing production processes and maintaining quality standards. Industrial weighing scales facilitate accurate measurement of raw materials, components, and finished products, enabling efficient inventory management and ensuring product consistency.

Logistics and Shipping

Efficient logistics operations rely on accurate weight measurements for inventory tracking, load planning, and shipping. Industrial weighing scales are indispensable in warehouses, distribution centres, and shipping terminals, facilitating seamless freight handling and compliance with transportation regulations.

Food Industry

In the food industry, strict adherence to weight specifications is essential for compliance with regulatory standards and ensuring product integrity. Industrial scales are extensively used in food processing facilities for portion control, recipe formulation, and packaging, helping to minimize waste and optimize production efficiency.

Types of Industrial Weighing Scales

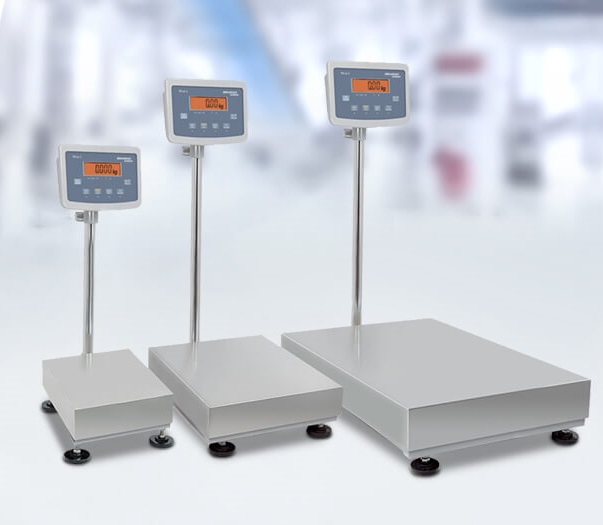

Floor Scales

Floor scales are robust platforms designed to withstand heavy loads and harsh industrial environments. Widely used in warehouses, factories, and manufacturing facilities, floor scales provide accurate weight readings for palletized goods, bulk materials, and oversized items.

Crane Scales

Crane scales are specialized weighing devices attached to overhead cranes or hoists, enabling the measurement of heavy loads during lifting and transport operations. These rugged scales are indispensable in industries such as construction, mining, and shipping, ensuring safe and efficient handling of bulky materials.

Truck Scales

Truck scales, also known as weighbridges, are large-scale weighing systems designed to measure the weight of entire vehicles and their cargo. Commonly used in transportation hubs, ports, and distribution centres, truck scales facilitate the accurate weighing of trucks, trailers, and containers, enabling compliance with weight regulations and optimizing load distribution.

Factors to Consider

Capacity

The capacity of an industrial weighing scale in Singapore refers to the maximum weight it can accurately measure. When selecting a scale, it’s essential to consider the maximum weight requirements of your application to ensure compatibility and avoid overload issues.

Accuracy

Accuracy is paramount in industrial weighing applications, as even minor deviations can have significant implications for product quality and process efficiency. High-precision scales with advanced calibration features ensure reliable and consistent measurement results, minimizing errors and optimizing productivity.

Durability

Industrial environments can be harsh and demanding, requiring weighing equipment that can withstand rugged conditions and heavy usage. Durable construction materials, such as stainless steel and reinforced alloys, ensure longevity and reliability, even in challenging operating environments.

Installation and Calibration

Proper Setup

Proper installation is crucial to the performance and accuracy of industrial weighing scales. Following manufacturer guidelines and ensuring a stable, level foundation are essential steps in achieving reliable measurement results and minimizing calibration errors.

Calibration Process

Calibration is the process of adjusting a weighing scale to ensure accurate and consistent measurement readings. Regular calibration by trained technicians helps maintain the integrity of the weighing system, compensating for environmental factors, wear and tear, and drift over time.

Maintenance and Troubleshooting

- Regular Maintenance: Routine maintenance is essential for preserving the performance and longevity of industrial weighing scales. Cleaning, lubrication, and inspection of critical components help prevent malfunctions, extend equipment life, and minimize downtime.

- Common Issues and Solutions: Despite their robust design and precision engineering, industrial weighing scales may encounter occasional issues due to factors such as wear, environmental conditions, or operator error. Prompt identification and troubleshooting of common problems, such as calibration drift, sensor malfunction, or connectivity issues, are essential for maintaining operational efficiency and minimizing disruptions.

Importance of Accuracy

- Impact on Business Operations: The accuracy of industrial weighing scales directly impacts various aspects of business operations, including product quality, inventory management, regulatory compliance, and customer satisfaction. Reliable weighing solutions ensure consistency, traceability, and compliance with industry standards, enhancing operational efficiency and competitiveness.

- Compliance Requirements: In regulated industries such as pharmaceuticals, food, and logistics, adherence to strict quality and safety standards is paramount. Industrial weighing scales play a crucial role in compliance with regulatory requirements, providing documented evidence of accurate measurements and ensuring product integrity throughout the supply chain.

Conclusion

Industrial weighing scale are indispensable tools in modern manufacturing, logistics, and food processing industries, enabling precise measurement, efficient operations, and regulatory compliance.