In order to keep homes and other buildings at a comfortable temperature, thermal insulation is used. It improves the efficiency of heating and cooling systems by lowering their energy consumption. Some of the materials used for dielectric coating include vermiculite, soil, polystyrene, cellulose, glass wool, rock wool, urethane foam, and soil. The R-value method can be used to determine the barrier’s effectiveness without taking into account other factors like the local environment or the construction quality.

Acoustic insulation

It reduces sound by using noise barriers, damping structures, anti-noise generators, and increasing the distance between the sound source and the receiver. With this kind of noise reduction, you can effectively reduce or absorb sounds. Apartments and other buildings frequently employ a combination of both approaches to achieve superior sound control. When there is less noise, sound waves can’t travel as far or between objects as they used to. Noise absorption employs echoes, reverberations, resonance, and reflection. Moisture is an important acoustic insulator because it can significantly reduce and sway the sound that travels through it.

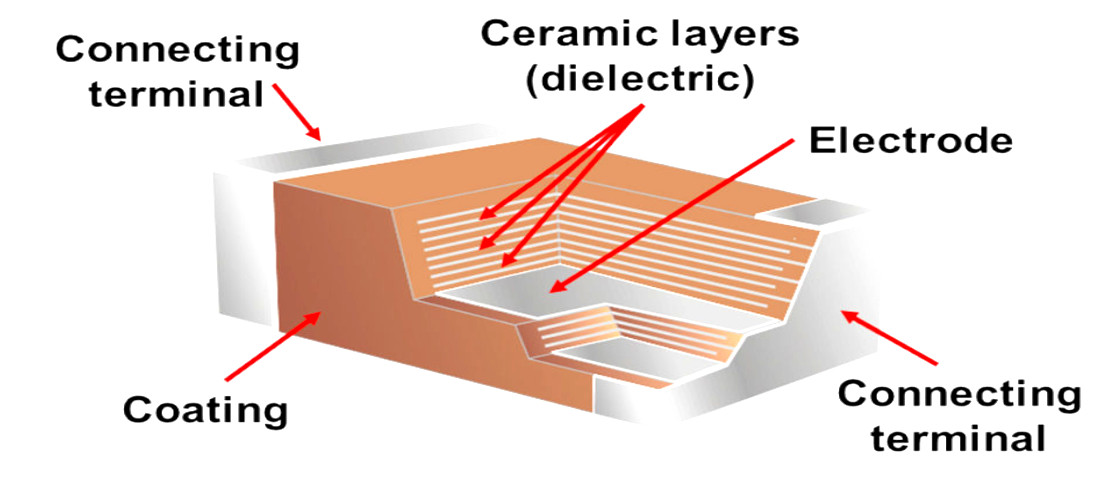

Material in electric insulation

Electrical insulation makes use of material that resists the flow of electric current in order to safeguard the transmission of electricity and keep fires and shocks from occurring. A material that can shield electrical wires must have strong bonds between its atoms. This kind of barrier can be used on electrical equipment, conductors, electric power transmission support, utility poles, or utility pylons. Electrical insulators include Teflon, glass, and paper. Rubber-like-looking polymers aren’t as good, but they do the job with less resistance, are useful, and safe for low to moderate voltage.

Choosing to install insulation

Many homeowners choose to install insulation to reduce their monthly costs and increase their home’s energy efficiency. Contacting an experienced and qualified energy auditor will help you decide where to install new insulation, depending on how much you already have and where you need more. In addition, they will evaluate the basement, attic, garage, walls, floors, and other structural insultation components to determine which type was installed first.

Home insulators

They come in a variety of shapes and sizes, based on their intended use, cost, and location of installation. Fiberglass blankets and rolls are used in walls, floors, and ceilings that have not been finished. Because they require masonry expertise, vermiculite or perlite pellets are popular for new construction or major renovations. Polystyrene foam boards can be used in low-slope roofs insultation with no ventilation for fire safety. Gypsum board must, however, cover the boards to a thickness of half an inch. Loose fill cellulose is frequently used in unfinished attic floors and other difficult-to-reach areas. Mineral rock wool or fiberglass work well in unconditioned ducts and other places that can withstand high temperatures.

Showered cementitious or phenolic froth can be utilized to add protection to completed regions that are now completed as well as in open new wall depressions and incomplete loft floors. Structural insulated panels made of foam board or straw core are used in the walls, ceilings, and floors of new construction projects.

Design and Application

The appropriate blend of synthetic polymers is used to create electric insulated mats. An anti-static ground mat or floor mat is made of various anti-static materials specifically designed to help eliminate electricity generated by friction. Insulation mats typically function when plugged into an earthed line in an electrical outlet. Because it is so crucial to discharge at a slower rate, a resistor will be used to ground the mat. As a result, these insulating mats guarantee the appropriate safety of the workers.

Professionals and industrial workers who are required to work in an environment where there is a constant risk of electric shock and death should use electric insulated mats. Insulating materials can be used to cover the floors under control panels, ensuring worker safety and making the infrastructure safer and more secure. Consequently, risks posed by any kind of current leakage are less likely to occur.

Electrical safety

It is a top priority for professionals and employees, regardless of the size of the electrical industry. Electrical installation systems are taking on an ever-increasingly significant role in terms of operational safety and dependability. The increasing complexity of the applications necessitates constant safeguarding of the electrical safety of the machines and employees.

Features of electrical insulation coating

Electric insulated mats are now one of the most important industrial resources due to their distinctive mechanical and physical properties. High voltage insulating mat is highly recommended due to its high insulation, excellent aging properties, and resistance to temperatures from very low to very low. Additionally, these mats are resistant to acids, transformer insultation oil, and alkalis in addition to being flame retardant. In some industries, this kind of insulator is more popular because of its high tensile strength, low cost, and high elongation.

Accessibility in the Market

The mat contains a conductive material that gathers static energy all through the whole assembling process. The insulation mat needs to be grounded correctly. Electric insulated mats are available from numerous well-known brands. These mats are of the highest quality and can be utilized in substations, power plants, and other locations. Insulating materials can be found in a wide range of designs and specifications today. Because of their affordability, adaptability, vivid colors, durability, and ease of cleaning, these eco-friendly mats are favored or greatly appreciated.

Conclusion

Protection mat is a significant modern material that exceptionally adds to the security and security of different insultation little as well as enormous scope business area. It is widely used in a number of power plants, high voltage panels, substations, HT and LT labs, and power transmission rooms because it is mostly used for different electrical purposes. In addition, numerous types of insulation materials are utilized in all other related commercial establishments where workers are required to perform close-to-ear control panels and bus bars to ensure workers’ safety and protection. The most common places to add insulation are attic spaces like access doors and knee walls, ducts, cathedral ceilings, exterior insultation walls, floors above unheated garages, and basement foundations or crawl spaces.